Due to the price of finished product five-axis head import is too large, and domestic five-axis head due to various reasons, the assembly tolerance control is difficult to ensure accuracy, and the five axis head of tolerance measurements are used manual measurement, measurement is difficult, high requirements of assembly workers, time is long, and AC vector Angle and the cutting tool center of rotation and axial vector Angle measurement is very difficult to use A manual measurement, result in five-axis machine tools machining precision is difficult to guarantee. At present, the standard ball measuring function of five-axis mechanism is only available in numerical control systems in Europe and Japan. RTCP five axis RTCP standard with five axis head standard ball measurement function, to solve the machine tool factory using homemade assembly five axis head tolerance measurement problem, RTCP use their own measurement of five axis mechanism tolerance data, software internal compensation mechanism tolerance, so that processing products quickly and accurately.

Moelling is a CAD option module for PowerMILL. Provide CAD model selection support for PowerMILL, which is used to prepare for machining model dressing.

In the PowerMILL programming environment, Moelling integrates 3D wireframe and curved surface CAD method into one, which is very powerful and convenient to use. It can repair, edit and create surface models, and can read data models of various formats directly, which can fully improve the work efficiency of programmers.

more >>

PowerMILL with its unique, efficient regional clearance method and the leadership of the city clearance processing trend. The basic point of this method is to ensure the stability of the tool load as much as possible and to minimize the sudden change of cutting direction. In order to achieve the above objectives, the bias machining strategy is used to replace the traditional parallel machining strategy in PowerMILL area clearance machining.

more >>

PowerMILL provides I 29 high speed finishing strategies, such as 3d bias, isometric and optimal isometric finishing, spiral and other strategies. These strategies can ensure the smooth and stable cutting process, ensure the fast cutting of materials on the workpiece, and obtain high precision and smooth cutting surface.

more >>

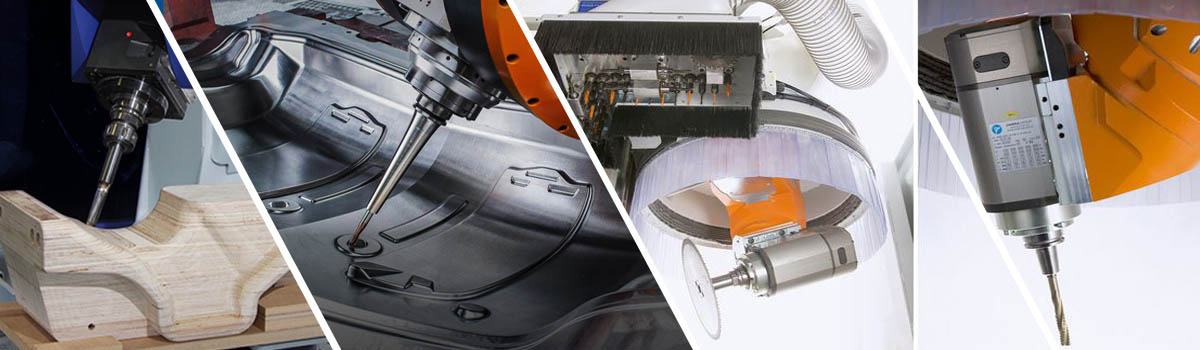

PowerMILL provides positioning 5 axis machining function and continuous 5 axis machining function.

PowerMILL's continuous 5-axis machining function allows the use of multiple machining strategies and a full range of cutting tools to generate 5-axis tool paths on complex surfaces, solids, and STL triangular models, all of which have been overcut checked.

more >>

Some 5 axis features of PowerMILL:

● direct 5-axis machining of STL model

● carry out motion simulation of 5-axis machine tool under programming environment to ensure processing safety;

● each processing strategy supports all tool types:

● interactive knife shaft editing, more convenient to use, more smooth knife shaft:

● intelligent identification of 5-axis normal drilling:

● support taper cutter for Swarf machining:

● support the C axis positioning function, control the direction between the spindle of the machine tool or the work table and the workpiece

more >>

● tool bar and clamping system interference inspection

The cutter path area where the collision occurs and the collision depth;

Automatic tool intervention path:

Minimum tool extension length required to avoid collision;

Set machining parameters according to different machining depths to improve machining efficiency;

● tool bar and clamping system interference checker

Allow users to customize add components;

Manage tool bar and clamping system data;

Load the existing tool bar and clamping system data:

Can be arbitrarily modified, preview tool bar and clamping system combination;

● very intelligent tool database

The new search function makes choosing a cutter easier

Cutting speed, speed and other cutting parameters and specific tool connected;

Support users to set up parameter database based on cutter:

Tool database can share with FeatureCAM:

● avoid errors that occur when defining tools separately, resulting in losses

● visual selection of tools and clamping parts - intuitive, fast

● it is convenient for the accumulation and standardization of process parameters

more >>

Due to the price of finished product five-axis head import is too large, and domestic five-axis head due to various reasons, the assembly tolerance control is difficult to ensure accuracy, and the five axis head of tolerance measurements are used manual measurement, measurement is difficult, high requirements of assembly workers, time is long, and AC vector Angle and the cutting tool center of rotation and axial vector Angle measurement is very difficult to use A manual measurement, result in five-axis machine tools machining precision is difficult to guarantee. At present, the standard ball measuring function of five-axis mechanism is only available in numerical control systems in Europe and Japan. RTCP five axis RTCP standard with five axis head standard ball measurement function, to solve the machine tool factory using homemade assembly five axis head tolerance measurement problem, RTCP use their own measurement of five axis mechanism tolerance data, software internal compensation mechanism tolerance, so that processing products quickly and accurately.

High-end products, CNC processing

High-end products, CNC processing Molding by high precision double swing head

Molding by high precision double swing head Timely delivery, guaranteed

Timely delivery, guaranteed Professional CNC processing

Professional CNC processing Professional services, no worries about after-sale service

Professional services, no worries about after-sale service